The amount of construction aggregates from recycled and secondary sources in Britain has reached an all-time high as producers invest in more advanced ways to turn ‘waste’ into valuable materials.

That’s one of the key findings of a new report from the Mineral Products Association (MPA) – which represents firms supplying over 90% of Britain’s aggregates – showing the total volume of recycled and secondary materials reached a record 73.5 million tonnes in 2022.

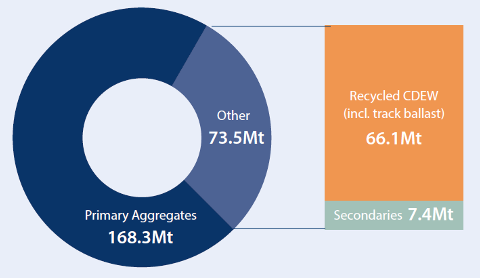

Total aggregates supply (million tonnes) in Great Britain, 2022

Total aggregates supply (million tonnes) in Great Britain, 2022

The data confirms that recycling rates in Britain are higher than any other major European economy – further evidence of the industry's long-standing commitment to resource recovery and efficient reuse, in line with circular economy principles. Processing includes crushing, segregating (removing metals, plastics, etc), washing and screening, and blending to create materials that meet technical specifications.

In the report ‘ Construction Aggregates Supply in Great Britain: Primary, Recycled and Secondary Aggregates in 2022’ the MPA demonstrates that non-primary materials accounted for over 30% of the country’s total demand for aggregates (which stood at 241.8 million tonnes in 2022, the biggest flow of materials in the economy).

Breaking the figures down further, the report says 60.3 million tonnes of recycled aggregates came from the recovery of construction, demolition and excavation wastes (CDEW) such as concrete and brick rubble, old rail track ballast and earthworks spoil. It also shows that 5.8 million tonnes of asphalt planings were processed for reuse in roads in 2022.

In addition, the increasingly important role played by industrial by-products like china clay waste and incinerator bottom ash (IBA) to make secondary aggregates is also highlighted, with 7.4 million tonnes of these materials produced in Britain in 2022.

However, the report also highlights the challenges in accurately tracking progress due to the absence of comprehensive national statistics. Recognising this, the MPA is leading industry efforts to address these data gaps to better inform evidence-based policymaking. Looking forward, the proposed introduction of a mandatory UK-wide digital waste tracking system in 2025 should also help enhance the availability and quality of the data related to construction and demolition waste.

Despite the record recycling figures the report also demonstrates the significance of primary aggregates (newly quarried or marine dredged) which still make up 70% of the country’s aggregate demand. The MPA has long flagged concerns about the shortcomings of a planning and permitting system which means replenishment rates for these materials is at an all-time low.

Mark Russell, the MPA’s Executive Director for Planning & Mineral Resources said: “Whilst the construction industry may well be the country’s largest source of waste, MPA members have become proficient in recovering materials arising from build development and processing them so they can be put back to good use elsewhere in construction. The most efficient way to process and reuse these materials is close to where they are sourced to minimise transport, and the bureaucracy of the planning and permitting system is often a barrier to delivering the most efficient solutions.

That said, there are major investments taking place to improve the quality and availability of recycled and secondary materials, giving developers and contractors the confidence to specify them. Even the small amount of soft inert waste that cannot be turned into aggregate is put to good use in quarry restoration and land remediation. Nothing is wasted!”

Author of the report Aurelie Delannoy, Director of Economic Affairs at MPA, emphasised the significance of recycled and secondary aggregates in meeting construction demands sustainably: “The substantial contribution of recycled and secondary aggregates to total supply is a huge but largely hidden success story for the industry. Aggregates producers have been recycling suitable construction and demolition waste for years to meet our construction needs as efficiently and sustainably as possible, whilst meeting stringent technical standards.”

“As we look ahead, further progress in recycling can be anticipated, supported by the major investments that have recently taken place in the extractive sector. However, it is important to recognise that the availability of recycled aggregates is inherently tied to demolition activity and the availability of suitable waste materials. With increasing demands to achieve climate neutrality by 2050 and address key infrastructure and housing needs, primary aggregates extraction will remain essential for meeting the majority of demand over the long term.”

Ends.

About the Mineral Products Association:

The Mineral Products Association (MPA) is the trade association for the aggregates, asphalt, cement, concrete, dimension stone, lime, mortar and industrial sand industries. With affiliation of the British Association of Reinforcement (BAR), the British Calcium Carbonate Federation, the Cement Admixtures Association (CAA), CONSTRUCT, Eurobitume, MPA Northern Ireland, MPA Scotland and the UK Quality Ash Association (UKQAA), it has a growing membership of 520 companies and is the sectoral voice for mineral products. MPA membership is made up of the vast majority of independent SME quarrying companies throughout the UK, as well as the 9 major international and global companies. It covers 100% of UK cement and lime production, 90% of GB aggregates production, 95% of asphalt and over 70% of ready-mixed concrete and precast concrete production. In 2021, the industry supplied £22 billion worth of materials and services to the Economy. It is also the largest supplier to the construction industry, which had annual output valued at £178 billion. Industry production represents the largest materials flow in the UK economy and is also one of the largest manufacturing sectors. www.mineralproducts.org

For media enquiries, contact Elizabeth Clements at: Elizabeth.Clements@mineralproducts.org